Protecting the World’s Largest Mirrors

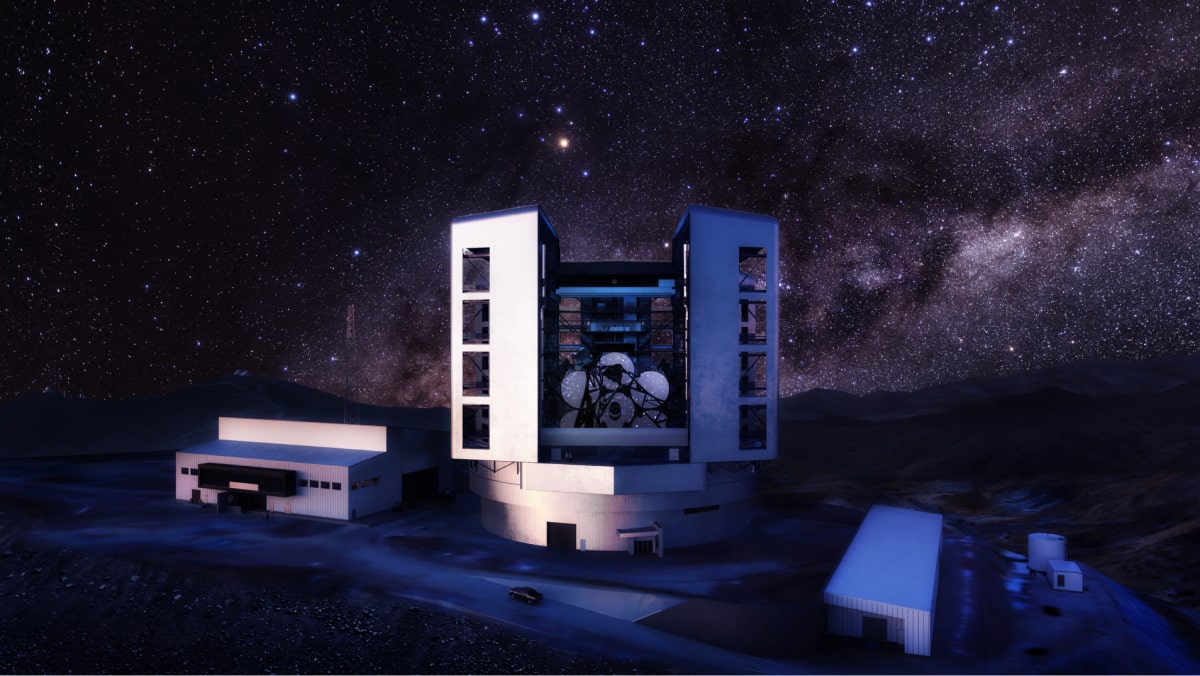

A look inside the Giant Magellan Telescope’s primary mirror support system

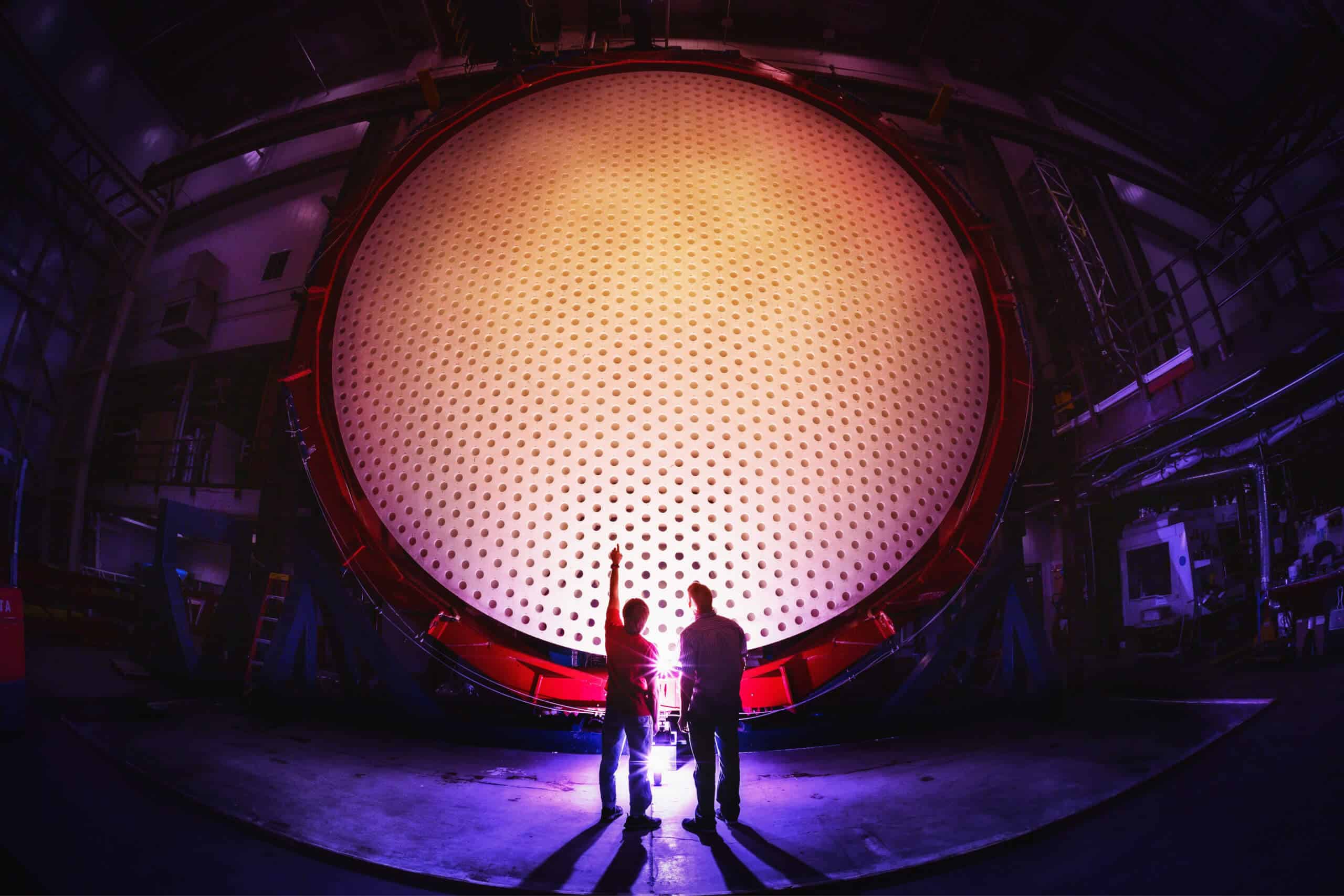

When far away light from an object in the universe is collected by a telescope, it first encounters a special surface called a primary mirror. These mirrors are fabricated to be as giant as possible so the human eye can see farther into deep space than ever before. They are also made to be as smooth as possible so that its surface has no imperfections greater than 1/1,000th the width of a human hair. Crafting a telescope’s primary mirror takes many years and is a marvel of modern engineering.

The Giant Magellan Telescope uses seven of the world’s largest and heaviest primary mirrors to collect light from the universe. Each are 8.4 meters in diameter, weigh 17 tons, and are arranged in a unique flower pattern to create a seamless 368 square meter light collecting surface. While the primary mirrors are incredibly important to the Giant Magellan’s ability to do science, the complex process of transforming the light it collects into science begins in the support system that protects these giant mirrors. Just below the monolithic 25.4-meter-primary mirror sits seven primary mirror support systems – also known as mirror cells – that act in unison to focus the light, align optical components and correct imaging deformations due to gravity and extreme temperature swings. Each mirror support system houses the most advanced optical technologies on Earth, including a thermal control and active optics system.

Meeting the active control requirements on large aperture telescopes, like the Giant Magellan, demands new innovations in technology. “Such advancements come with many technical risks which require detailed prototyping and testing of the engineering designs,” shares Trupti Ranka, a senior control systems engineer for the Giant Magellan.

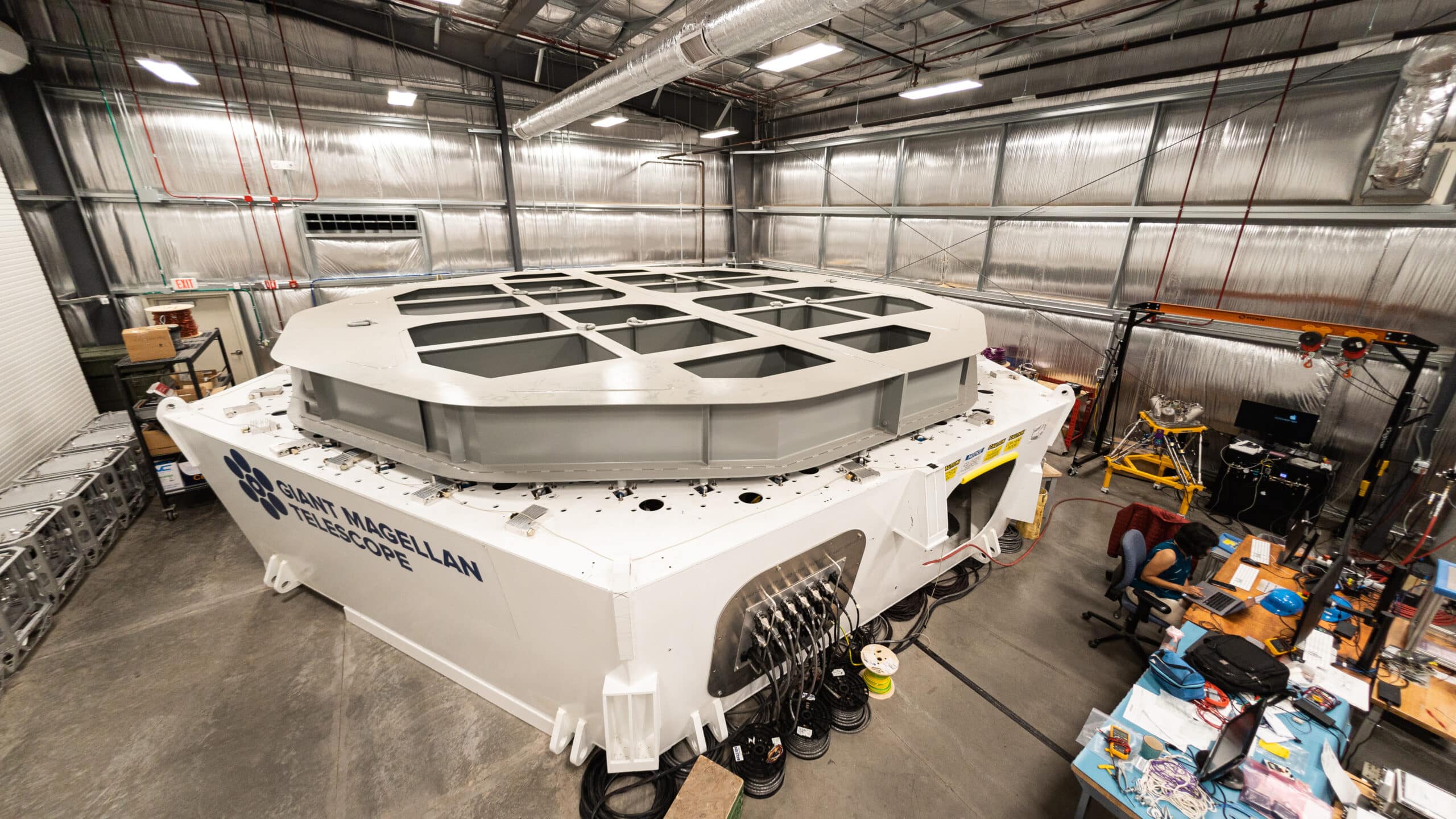

Each mirror support system must be compact and lightweight for the telescope to be stiff and stable in resisting image quality interruptions. As a precursor to the fabrication of the seven mirror support systems, a full-scale prototype has been built to validate design decisions and demonstrate the performance. The prototype includes the hardware and software that control the shape, position, and thermal state of a 17-ton single primary mirror on the Giant Magellan. The precision control technologies within the mirror support system allow for real-time shaping and positioning within 200 nanometers. With this, all seven primary mirrors work in concert, behaving as one monolithic 25.4-meter mirror.

Active Optics System

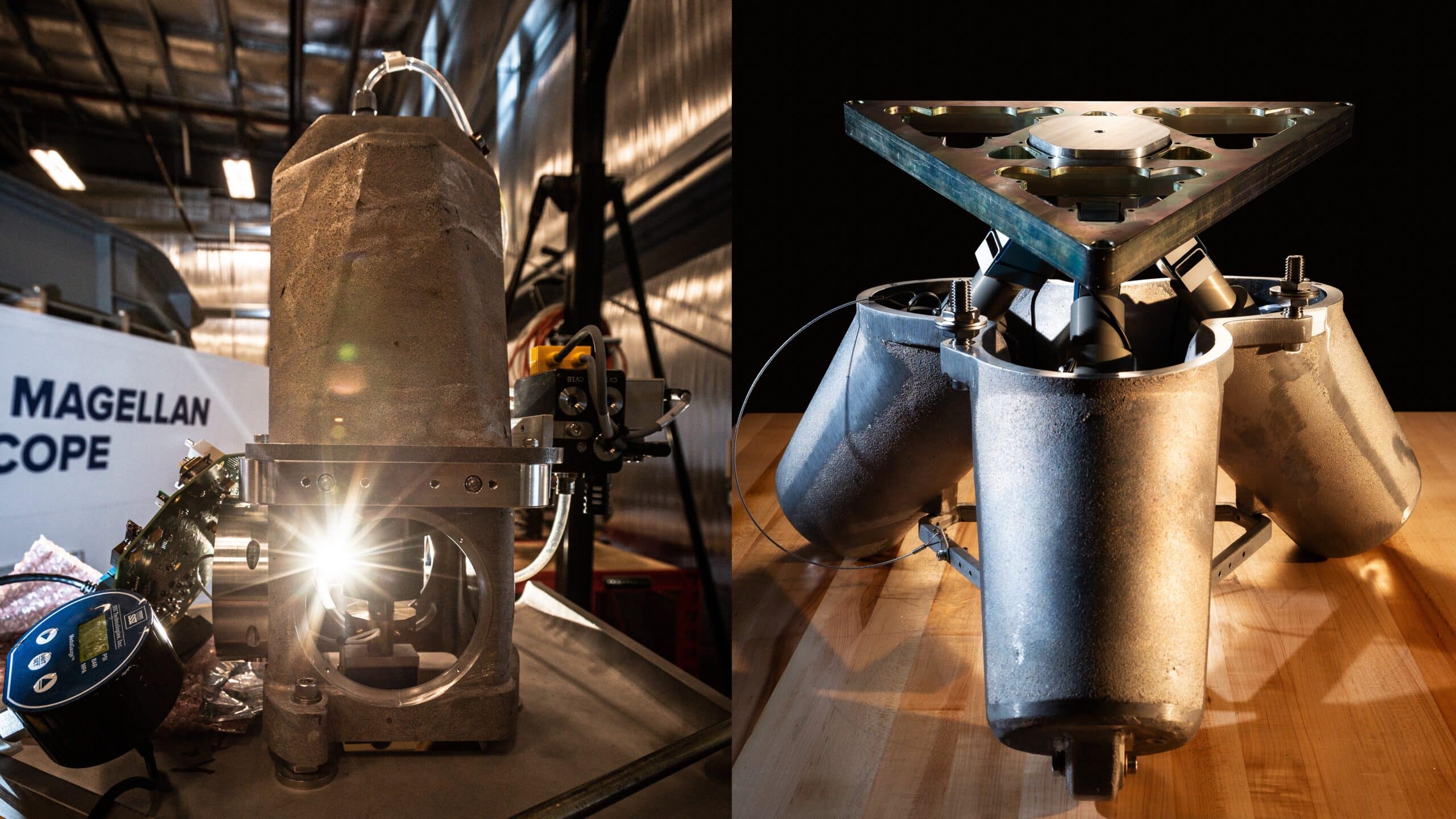

An array of interface features is attached to the mechanisms that support and control the primary mirror – active supports and static supports. Active supports include 170 pneumatic actuators that lift and shape the primary mirror through applied force, as well as six linear actuators that position the primary mirror in six degrees-of-freedom.

While the active supports allow for precise control of the primary mirror figure and position, the static supports hold the primary mirror in its resting position with wire rope isolators. The telescope will be exposed to regular seismic events in Chile’s Atacama Desert – one of the most seismically active regions in the world. During an earthquake, over 300 static supports work to secure the primary mirror by lifting it against gravity through distributed forces to its back surface. All while combating excessive stress on the glass from the elastic and thermal deformation of the steel weldment. Ranka shares that in addition to the static supports, “dampers, that have the same function as shock absorbers in our cars,” have been implemented into the actuators to mitigate the motion of the glass during an earthquake.

Thermal Control System

Simulation of the magnitude of refractive index spatial gradient distribution on the telescope enclosure mid-sectional plane. The Giant Magellan’s computational fluid dynamics model is used to simulate and analyze the aero-optical environment around the observatory. Credit: Giant Magellan Telescope – GMTO Corporation

Simulation of the magnitude of refractive index spatial gradient distribution on the telescope enclosure mid-sectional plane. The Giant Magellan’s computational fluid dynamics model is used to simulate and analyze the aero-optical environment around the observatory. Credit: Giant Magellan Telescope – GMTO Corporation

“As the night air cools, the mismatch in temperature between the air and the primary mirror causes localized turbulence. To minimize this effect, called the seeing effect, it is important to match the temperature of the mirror to the ambient air around it,” shares Ranka. A closed-cycle forced-air convection system is used to maintain a thermal equilibrium within the telescope enclosure and reduce thermal gradients across the primary mirror surface. Fourteen air handler units utilizing CO2 based refrigeration – the first system of its kind used for telescopes – are mounted to the interior of the mirror support system to circulate the air.

Prototype Testing

At the University of Arizona Tech Park, the prototype has undergone functional, performance, and safety testing with a steel surrogate mirror, simulating the mass, center of gravity, and stiffness of a primary mirror. Last year, the synchronized functions of all components were successfully demonstrated in a raising sequence of the surrogate mirror. Ranka described, “in this sequence the weight of the surrogate mirror is carefully offloaded to the force actuators from the static supports and able to move freely in a controlled fashion.”

Sequence of raising the surrogate mirror off the static supports, translation of the surrogate mirror along the Y-axis +/- 6 mm at a max speed of 50 um/sec, returning to the nominal position, and lowering onto the static supports. Credit: Giant Magellan Telescope – GMTO Corporation

Sequence of raising the surrogate mirror off the static supports, translation of the surrogate mirror along the Y-axis +/- 6 mm at a max speed of 50 um/sec, returning to the nominal position, and lowering onto the static supports. Credit: Giant Magellan Telescope – GMTO Corporation

Of the seven primary mirrors, three are complete and three are in various stages of fabrication at the University of Arizona Richard F. Caris Mirror Lab. The most recently completed primary mirror has been primed for integration into the prototype later this year for significant testing. This testing will serve as the dress rehearsal for all seven primary mirrors. In anticipation of the testing, Ranka expressed that “this is the only chance to ensure the integrated mirror support system can control the optical surface of the primary mirror as needed.”

To learn more about the Giant Magellan’s supporting structure, explore the telescope mount and view our image gallery of the fabrication.